Jesse Remillard, ERS, for Zondits

Connecticut’s GS Thermal Solutions has developed the premier commercial liquid-cooled LED grow light on the market. The company also specializes in grow-room engineering, with a focus on providing whole system designs for commercial growers that maximize efficiency. Zondits spoke with the CEO and Vice President of Business Development to understand the benefits that their products offer to indoor growers.

This interview assumes that the reader has a basic understanding of grow lighting and grow room dynamics. For the unfamiliar reader, please see this more generalized LED grow lighting Zondits interview.

- Can you describe the products and services that GS Thermal Solutions offers?

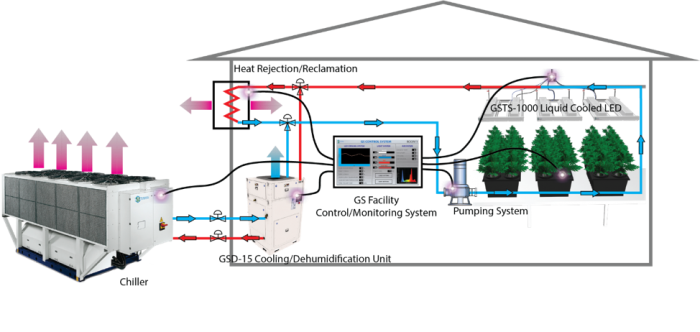

GS Thermal Solutions offers individual energy efficient products/equipment, but we also focus on a complete indoor grow system. A completely integrated system allows each component to be fine-tuned to work with other components to maximize the benefit and efficiency.

GS Thermal Solution’s products include:

- GSD-15 Cooling/Dehumidification Unit (15 tons)

- GSTS-1000 Liquid Cooled LED

- GS Facility Control/Monitoring System

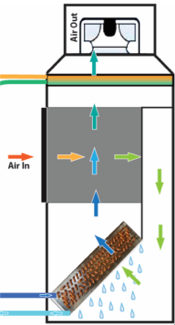

The GSD-15 Cooling/Dehumidification Unit uses an innovative air-to-air heat exchanging process to take full advantage of the cooling and heating from its working environment to maximize the efficiency. This unit can not only work with various chillers available, but it is designed to maximize the chillers’ performance and efficiency. When it combines with chillers that include an economizer, the cooling/dehumidification unit can utilize cold outdoor air to maximize free-cooling and reduce the cooling/dehumidification energy consumption.

The GSTS-1000 Liquid Cooled LED is already a highly efficient lighting system. However, within the complete GSTS system, waste heat from the light fixture can be reclaimed (for tempering water, space heating, dehumidification reheat process, etc.) for further reductions to the overall facility energy consumption.

The GS Facility Control/Monitoring System provides high-level feedback at each piece of equipment in the facility, from plant nutrient feeding, to the environment and control of its operating conditions, in order to communicate with other equipment and optimize the overall facility efficiency.

2. How/why do liquid-cooled LEDs generate energy savings over HID or air-cooled LEDs?

LEDs have a multitude of advantages over HIDs that result in energy savings and better performance. These include higher efficacy, directionality, and spectral intensity control. Also, unlike HIDs, which generate significant amounts of radiant heat, LEDs generate very little radiant heat. Most of the LED wasted heat conducts to the back of the LED. Therefore, LED fixtures are better suited to liquid cooling arrangements.

Since the LED technology is 45% efficient, that means 55% of the total energy still becomes waste heat in the light making process. Unlike air-cooled LEDs which reject waste heat into the grow environment, GSTS Liquid Cooled LEDs remove almost all waste heat through a circulating liquid loop. The waste heat from the light can then be reclaimed for other uses.

3. How do liquid cooled LEDs interact with the HVAC systems and environmental requirements of grow spaces?

The waste heat from the GSTS LED grow light is removed by the liquid cooling system out of the grow environment. This results in much less cooling load than other systems have. This wasted heat can also be repurposed for heating hot water or directed back to the GSTS dehumidification system for the reheat process. This has great advantages for multilevel and tight space grow environments where heating and cooling is a challenge.

4. I understand that your lights include a high level of spectra control. How much of a learning curve is associated with using your systems, and do you have any testimonials that can attest to yield improvements using your equipment?

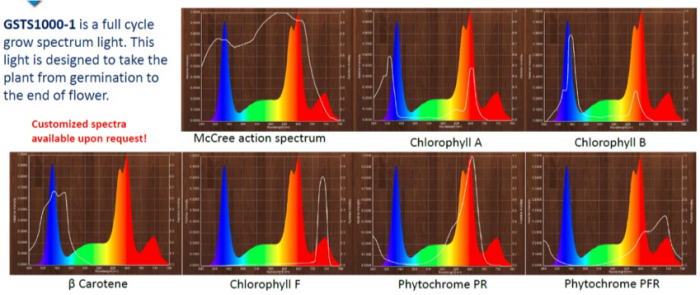

GSTS spectral output is designed to the McCree Action Spectrum, which is a measure of the usable light spectrum by plants that was developed in the 1970s by K.J. McCree. The McCree action spectrum provides a basis for the definition of photosynthetically active radiation (PAR) and is shown below with action spectrums for several different types of plant photoreceptors as a white line, overlaid on the spectral output of a GSTS light. Note that GSTS LED light spectral intensity can be tuned for any particular plant’s genetic stages of plant growth, by independently adjusting the output of each color LED on the fixture.

By having spectral intensity control, customers can always start with whatever they like best and adjust from there. Some of our most recent feedback has been that the grower was excited that they can record light “recipes,” or the spectrum used for each stage of the grow cycle, for future use and reference with grow cycle results. This also allows the customer to record and develop their “recipes” for specific strains of plants. With their new spectrum control, the customers’ ability to adjust the spectrum to the plants’ needs has benefits on many fronts, including THC and CBD production, shorter grow cycle, and increased yield.

5. Is there additional infrastructure and/or maintenance that is required? Do you provide support services, or training of any kind?

There is very little additional infrastructure and maintenance. The liquid flows in a closed loop fashion and requires little to no maintenance. The piping system is made from off-the-shelf PEX tubing, which is similar to a radiant floor heating system. Yes, installation support is always available. The system does not require any specific tradesmen; in fact, an end user with basic handyman skills could install the system.

6. What are the interactive impacts of liquid-cooled LEDs on system design and cost? The fixtures are more expensive and require additional systems to support them (pumping and heat rejection equipment), but do liquid-cooled LEDs offset or reduce the sizing of other components of HVAC systems?

Since the liquid-cooled LEDs significantly reduce the sensible cooling load, equipment can be sized smaller, yielding significant savings in HVAC equipment and electrical infrastructure. The operating cost is also significantly reduced due to the smaller size of the equipment.

7. Do you warranty your lights?

Yes, we have a standard 3-year warranty and an option for an extended 5-year warranty.

8. Will LEDs ever be the standard for grow lighting like they are for space lighting, and if so, how long until we get to that point?

We have been seeing a change over the last 6 months with significantly high adoption from growers than compared to the past couple years. People are realizing the science and benefits of the LED technology. With LEDs continually improving and reducing in cost, we think it will not be more than 2 years before LEDs become the standard for grow lights. However, not all the LEDs are created equal, what will set one LED grow light apart from the other is still a question, and GSTS research and development team will continue working to provide the solutions for this market.